Implementing Barcodes in GMP Biologics: Overcoming Challenges & Choosing the Right Software

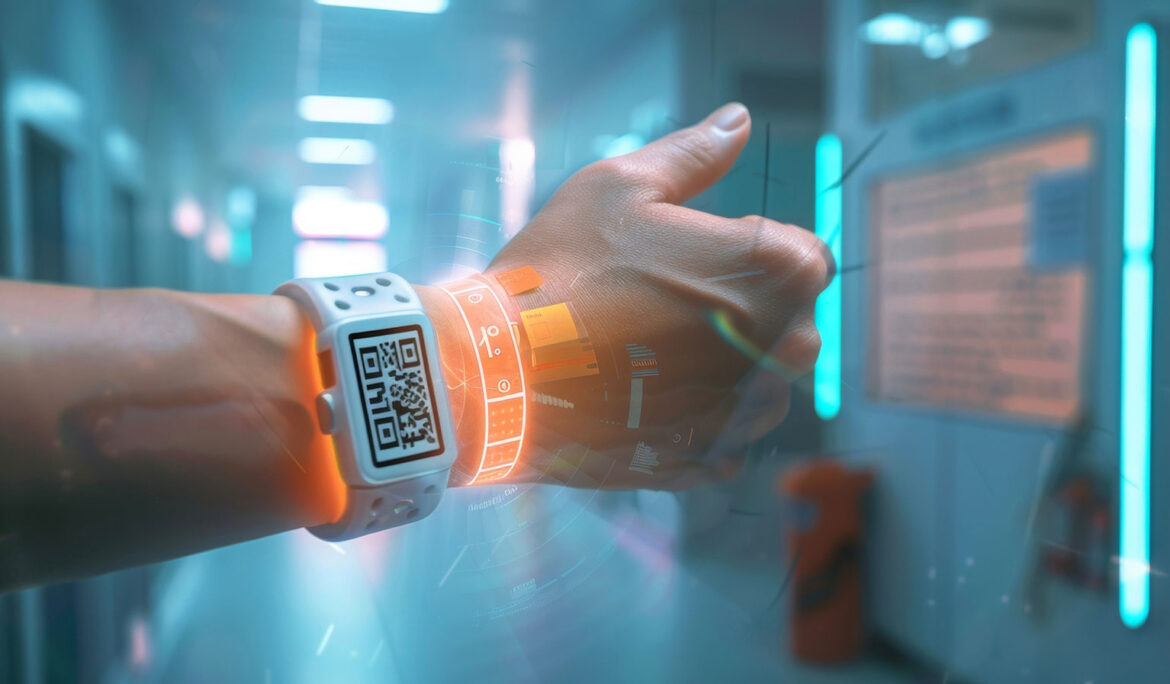

The implementation of barcodes in GMP (Good Manufacturing Practice) environments for patient-centric biologics handling firms can seem daunting. While the benefits are undeniable, the transition often presents challenges. Let’s delve into the practical difficulties and how the right software can ease this process.

Challenges of Barcode Implementation in GMP Biologics

Complex Workflows: Biologic manufacturing processes are often intricate, involving multiple stages and numerous materials. Mapping these workflows into a barcode system can be complex and time-consuming.

Data Integrity Concerns: Ensuring accurate data capture and preventing errors is crucial in GMP environments. Barcode systems must be reliable and robust to maintain data integrity.

Labelling Considerations: Biologics often require specific labeling for different stages of production, storage conditions, and regulatory compliance. Designing and printing suitable labels can be a logistical hurdle.

Integration with Existing Systems: Seamless integration with existing systems like LIMS (Laboratory Information Management Systems) or ERP (Enterprise Resource Planning) is essential for streamlined operations. This can sometimes require custom development or middleware solutions.

Training and Change Management: Introducing new technology requires comprehensive training for staff to ensure proper usage and adoption. Resistance to change can also be a factor.

Why Barcode and RFID Support in Software is Essential

Choosing a software solution that natively supports barcode and RFID (Radio Frequency Identification) technologies can significantly alleviate these challenges:

Streamlined Implementation: Software with built-in barcode and RFID functionality simplifies the implementation process, reducing the need for extensive customization or integration.

Enhanced Data Accuracy: Barcode scanning eliminates manual data entry errors, ensuring accurate tracking of materials and products.

Real-time Tracking: RFID technology enables real-time tracking of products throughout the supply chain, providing valuable insights into inventory levels, location, and status.

Improved Efficiency: Automated data capture and tracking through barcodes and RFID significantly improve operational efficiency, reducing manual labor and freeing up staff for higher-value tasks.

Cost Considerations for Barcode Printing

The cost of implementing barcodes can vary depending on the scale of operations and the chosen technology. While there is an initial investment in barcode printers and labels, the long-term benefits often outweigh the costs.

Printer Costs: Barcode printers range in price depending on their features and capabilities. Industrial-grade printers are more expensive but offer greater durability and performance for high-volume printing.

Label Costs: Label costs depend on the material, size, and quantity. Specialized labels for cryogenic storage or harsh environments may be more expensive.

Return on Investment (ROI): While there are initial costs, the ROI from barcode implementation can be significant. Improved efficiency, reduced errors, and enhanced compliance can lead to substantial cost savings in the long run.

Implementing barcodes in GMP biologics manufacturing may present challenges, but choosing the right software solution with integrated barcode and RFID support can streamline the process. By carefully evaluating your needs and selecting a vendor with expertise in the life sciences industry, you can overcome these hurdles and unlock the full potential of barcode technology to enhance your operations. While there are costs associated with barcode printing, the long-term benefits in terms of efficiency, accuracy, and compliance often outweigh the investment.